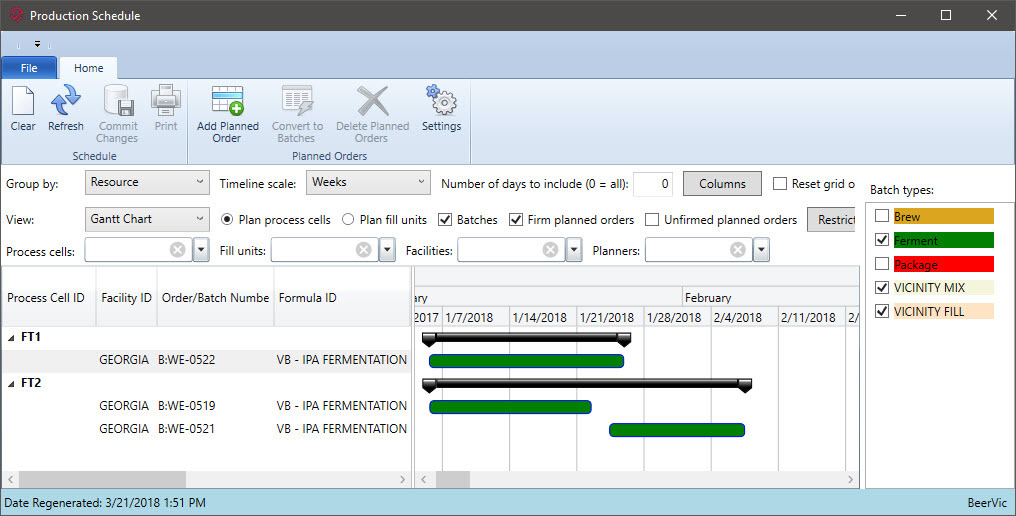

Schedule by Tank

Can your Excel-based system schedule tank resources and when a change is made that affects another part of the system — like purchasing?

Breweries struggle to create, maintain, and communicate the brew and fermentation schedule. When this is done in Excel, the data is not shared with any other part of the system — like MRP. VicinityBrew displays the schedule by the tank for the cellar. Tank conflicts and idle time are easily identified and corrected.

• The beer production schedule can be displayed by tank ID

• Logs can be moved to different days, shorten or lengthen the fermentation, and moved to different tanks

• Take tanks offline for cleaning or repairs with little effort

• Share and publish the schedule for external users to review

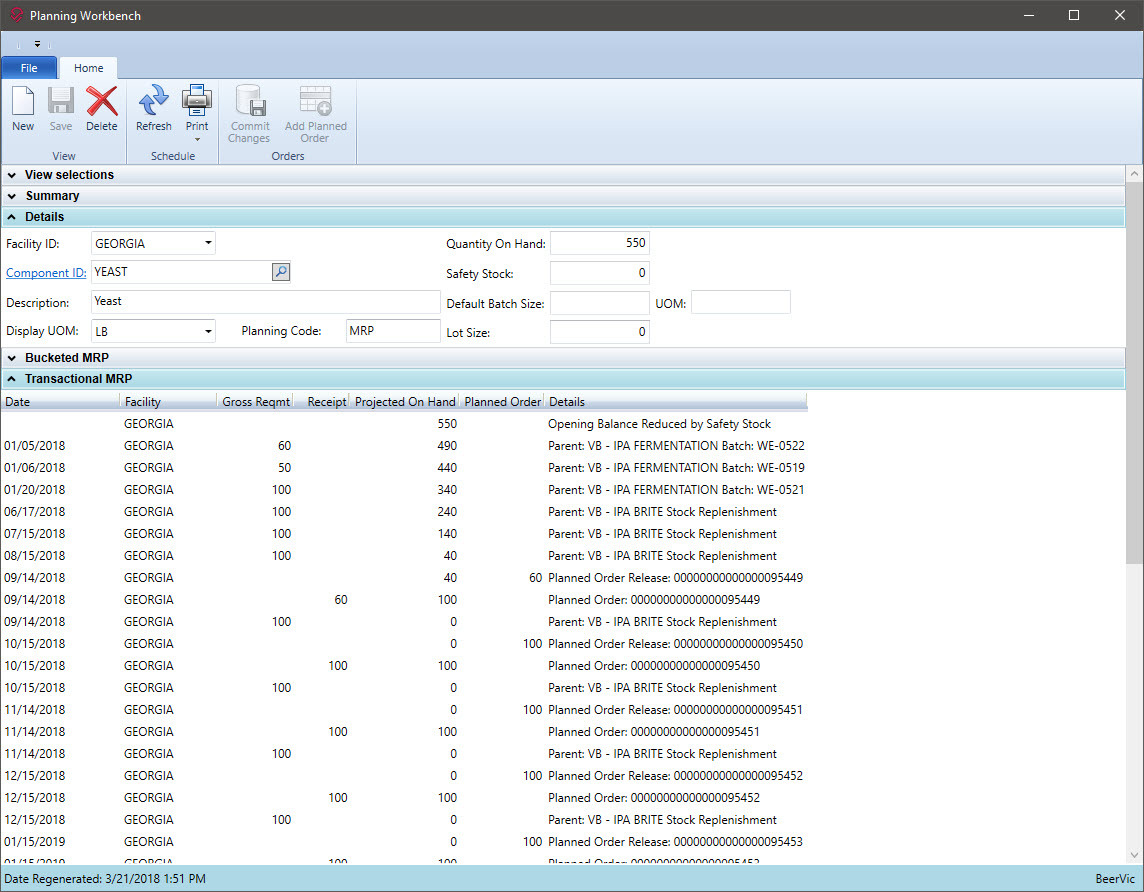

Material Requirements Planning (MRP)

How do you currently determine ingredient requirements for beer production weeks or months away?

VicinityBrew assists the scheduler to determine what ingredients, wort, or brite beer will be required to satisfy the anticipated sales demand of the brewery. With an MRP integrated into the production schedule, all anticipated shortages are easily identified and corrected.

- Visualize the raw materials needed for production, based on sales and production demands, with VicinityBrew Material Requirements Planning (MRP)

- Order raw materials and plan production much easier with Material Requirements Planning

- Outline your production schedule based on sales orders and forecasted demand

- Account for inventory dedicated to currently planned production orders and batches in process

- Plan requirements for as many raw material items as needed, with customizable Unit of Measurement (UOM)

- Set your raw materials’ minimum safety stock, production lead times, and purchase lead times

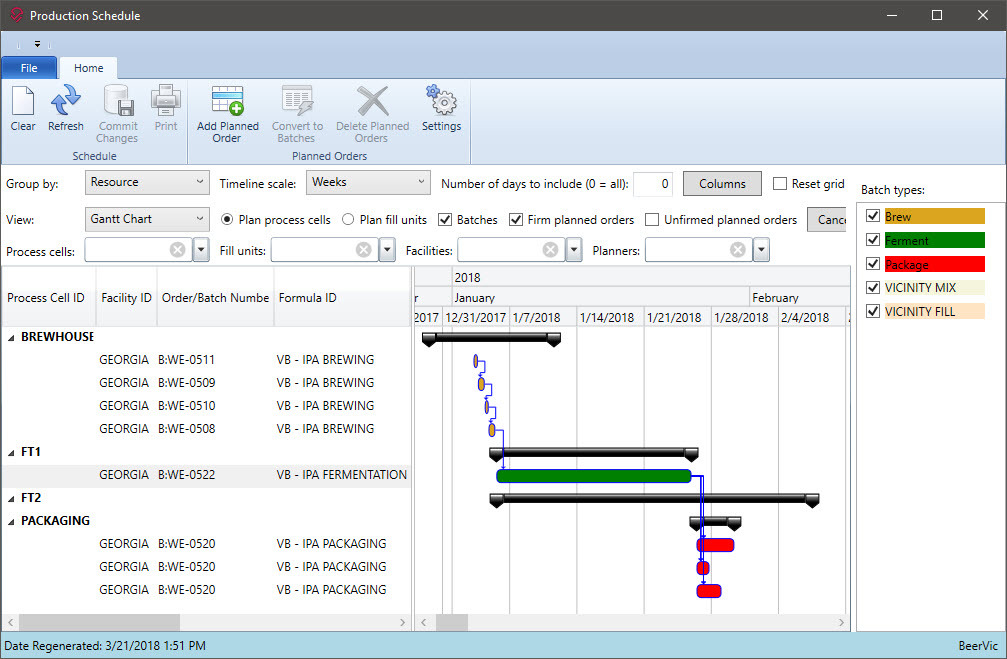

Visual Calendar

In your existing system, can you drag and drop production to different days or different tanks?

Scheduling requires a visual representation of what is planned for beer production. VicinityBrew allows the scheduler to review the existing plan and modify the schedule with an intuitive Gantt chart scheduling tool. Never has it been easier to schedule the brewhouse, cellar, and packaging areas.

- Schedule production and replace whiteboards and spreadsheets with VicinityBrew’s interactive digital calendar

- Utilize Flexible View: filter by day, month, year, type of production (brew, fermentation, packaging) or piece of equipment (brewhouse, fermenter, brite tank, packaging line)

- Highlight scheduling conflicts overlapped in a specific tank

- Open an existing production log or create new production logs by simply double-clicking

- Use a simplified user interface to easily make quick adjustments, including a drag and drop feature, enabling users to make changes on the fly

- Automate notifications of shortages or new orders not accounted for

- View a real-time representation of the brewery’s production schedule

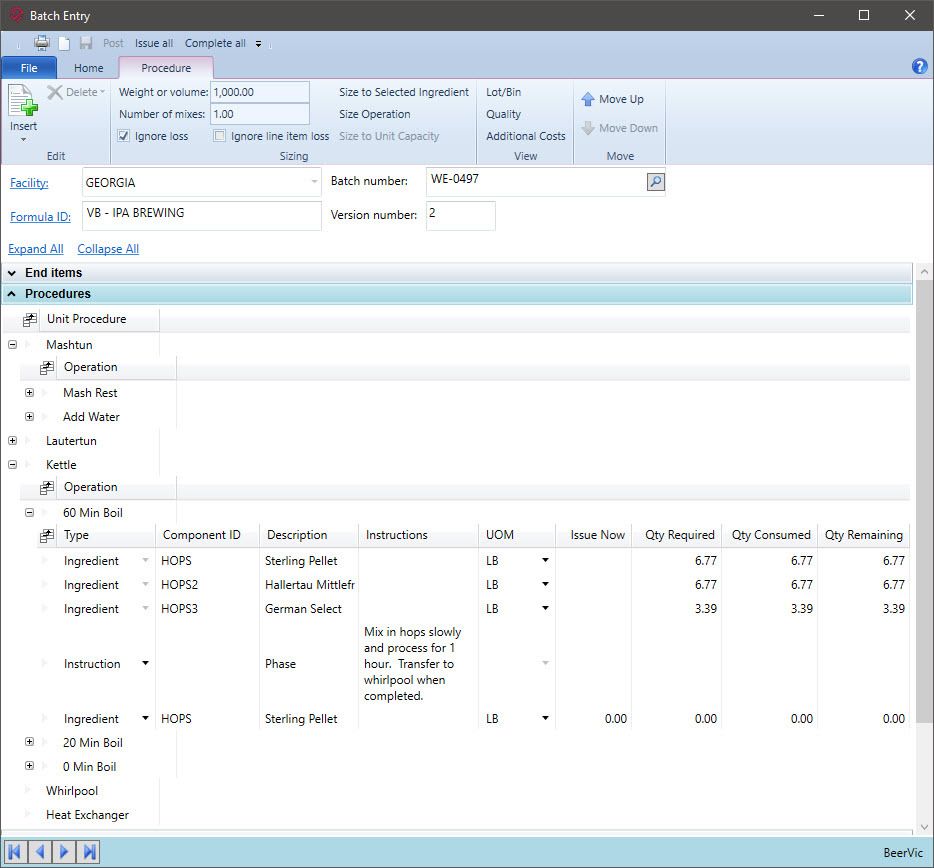

Brewery-specific production setup

Do you have a process that is unique to your brewery? Do you produce sours or barrel age? Are you crafty within the craft industry?

Not all breweries are made the same. Each has their own characteristics and each does this slightly different than the next. VicinityBrew allows you to define your processes the way you do them and not the way the software thinks you should do them. If flexibility is what you need, VicinityBrew delivers.

- Group beer production by brand or recipe to drive out demand at the brite beer level

- Create multiple finished good items from one single batch ticket.

- Bypass the creation of source production logs for each individual end item (bottle, keg, can)

- Blend tanks with tank blending by combining/consuming batches into a single log

- View all brews in process by style or brand

- Utilize a flexible unit of measure conversions from finished good items: cases, cans, barrels, gallons, etc.

forecasting

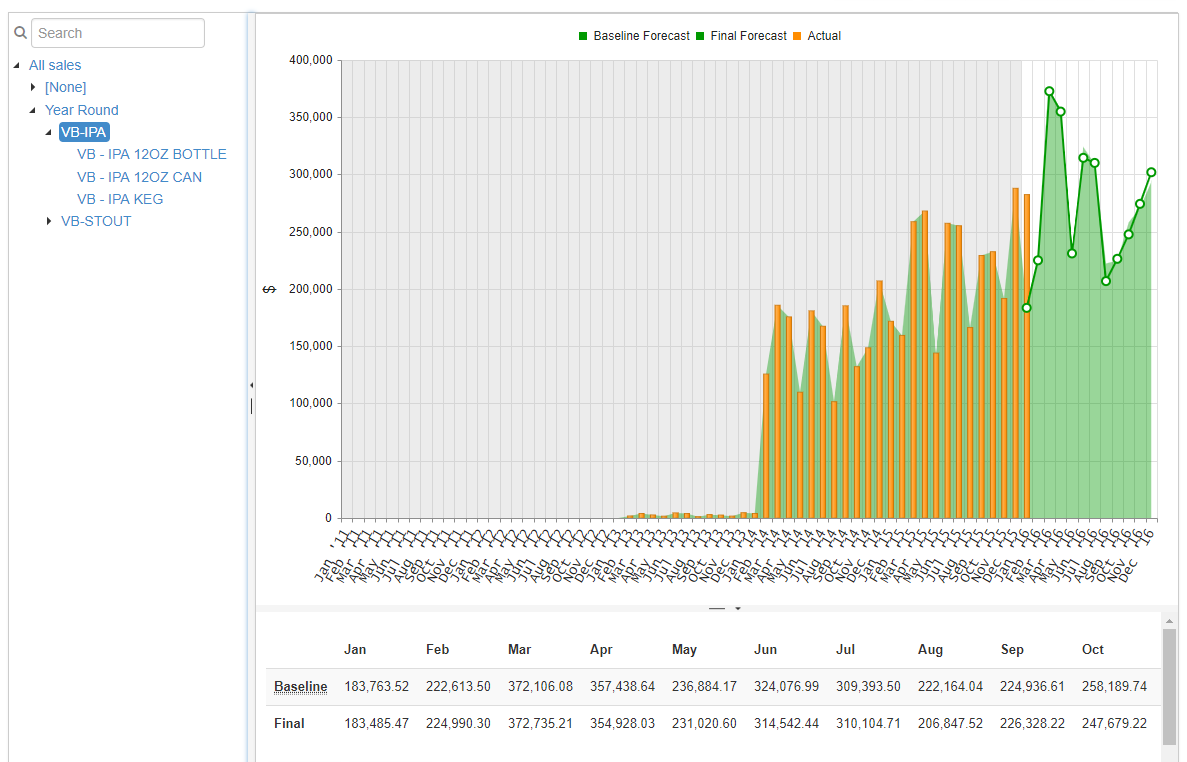

How do you handle forecasting today? Is it a series of disconnected spreadsheets with little input from other data?

Forecasting for a brewery is important because the lead time to make the beer far exceeds the order lead time. You can not make beer as fast as customers demand it. Therefore, it's important to have an integrated forecasting tool. VicinityBrew offers a couple of options, depending on how you forecast.

- Export historical depletions to plan for future demands more accurately

- Generate intuitive daily, weekly, or monthly forecasts based on historical sales

- Import data easily from anywhere using CSV files, or connect your forecast with the live API integration with forecasting software such as HaloBI

- Connect forecasts directly to MRP engine to read demand against sales orders, current production, and inventory levels

- Automate unit-of-measure conversions from end item SKUs to gallons or barrels

- Detect seasonal trends and whether trends exist for each of your brews

- Take advantage of VicinityBrew forecasting, which takes care of all the heavy lifting to make sure that forecasts are reconciled across all levels of your forecasting hierarchy