Recipe Management Software

Does your brewmaster currently store recipes in Excel or a shared document like Google Sheets?

VicinityBrew provides a central location to store brew, fermentation, and packaging formulas. All logs draw from this location when created, making sure everyone is working from the same data.

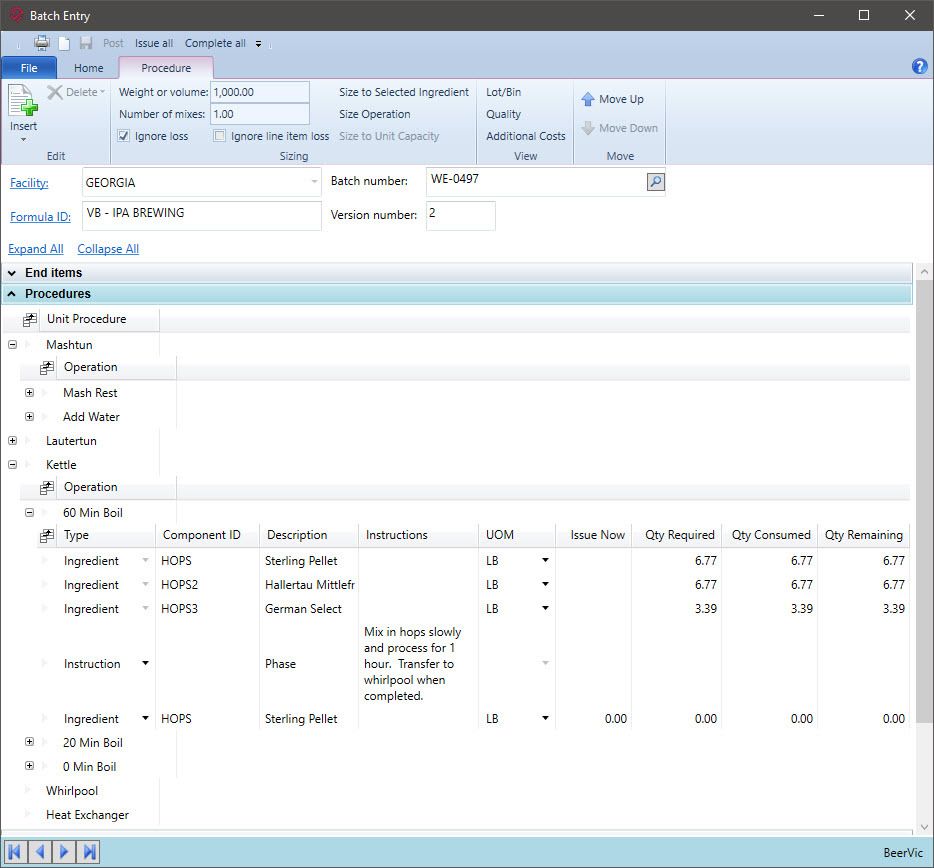

- Manage production by process or recipe for a more granular record of production

- Easily map recipes and fully integrate them with your financial BOM

- Brewmaster can define process steps and collect unlimited quality results directly on your production log

- Utilize flexible units of measure to simplify conversion between barrels, liters, kegs, cans, cases, etc.

- Calculate and analyze variances in your production process — easily identify loss and batch yield

- Identify labor, equipment, and raw material fluctuations in finished good production

Real-time material costs

Does your existing system automatically update ingredient costs with new purchases, or do you have to maintain the ingredient costs manually in your spreadsheet?

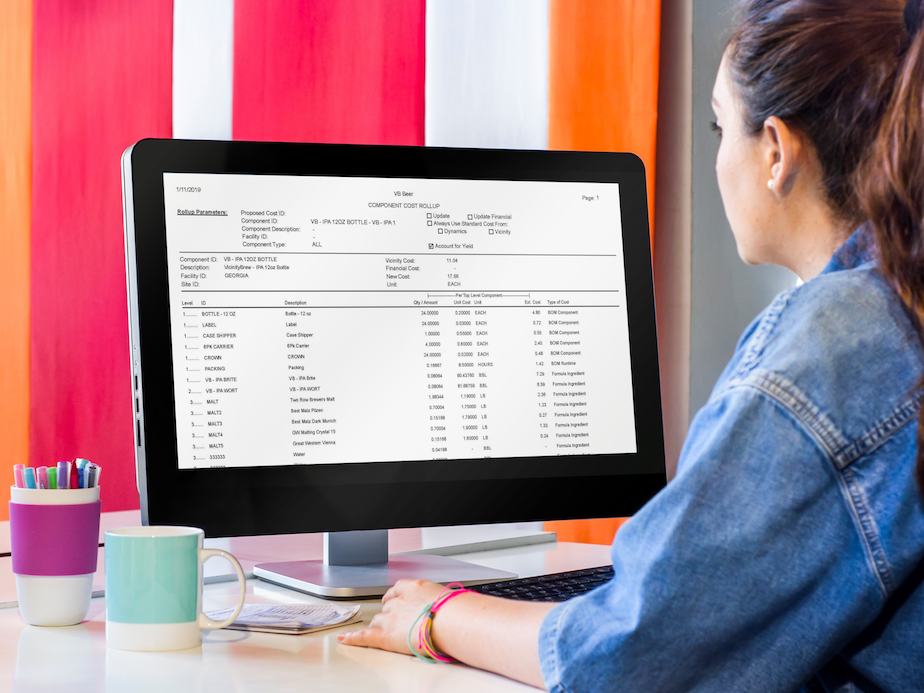

During recipe development, having the current ingredient costs available to the brewmaster is important in calculating the total production costs. VicinityBrew integrates purchasing with recipe management and creation. As soon as actual ingredient costs change for purchasing they are also seen by the recipe management software.

- Update inventory automatically for accurate costs and quantities with real-time purchase receipts

- View the latest product costs organization-wide, with no additional work from the purchasing department

- Utilize the Component Cost Roll Up Report, a complete BOM breakdown of the unit cost identifying each element consumed in an individual finished good item, such as hops, water, crowns, bottles, etc.

Inventory Costing

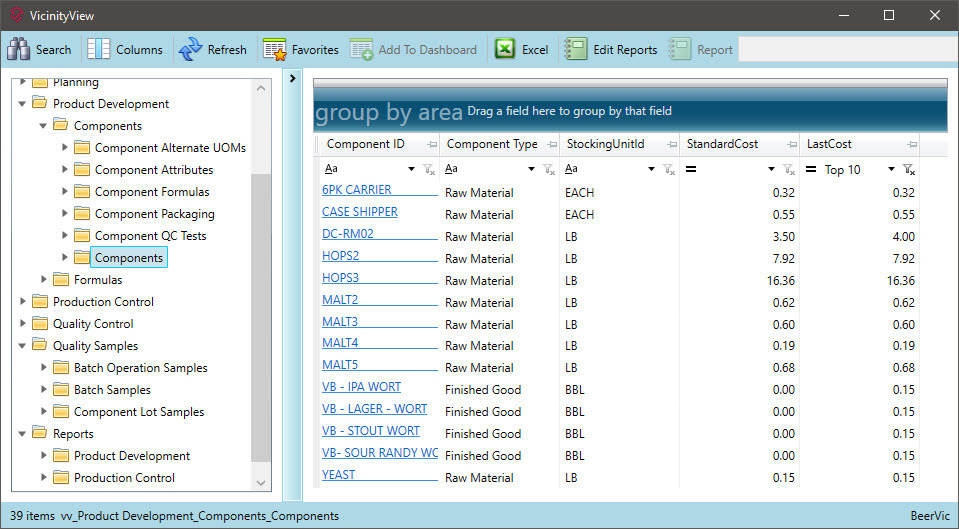

How do you currently value your inventory? Is it using last cost, average, or standard? Do you have a choice?

How inventory is valued in your system can provide important feedback to your production costs. Some items are better suited for standard costing and others a more actual method like FIFO or Average. VicinityBrew gives you the flexibility to define the costing method for any group of items, making your cost-of-production calculations more reflective of the products being produced.

- Use standard or actual cost valuation methods, VicinityBrew supports FIFO, LIFO, Standard and Average

- Vary your costing method by brew stage...actual cost wort until consumed into fermentation and cost your packaging batch at standard

- Get tighter cost reporting while streamlining finished goods on hand

- Review scenario-based impacts of certain price changes on overall production cost with the Proposed Cost Analysis Report